Seal Test / Sealing Test vendor|Radial Shaft Seal Testing : trading This Ink Pouch test or the Dye leak penetration test will show any irregularities that occur (e.g., channels of ink in the seal are a sign of a poor sealing process) and become visible immediately after the single-use dye test pack. It is easy to use, and the process can be documented. (See Figure 2).

WEBVídeo do TikTok de ALEATÓRIO_CALISTENIA (@aleatorio.calistenia): "quando eu fui bom , me ensinaram a ser ruim".som original - ALEATÓRIO_CALISTENIA.

{plog:ftitle_list}

WEBSomething went wrong. There's an issue and the page could not be loaded. Reload page. 174 likes, 5 comments - ludvick_personal on December 26, 2023: "🏋🏻♂️ . . #gym #body #shape #muscle #fit #br #rio #carioca".

Seal Testing

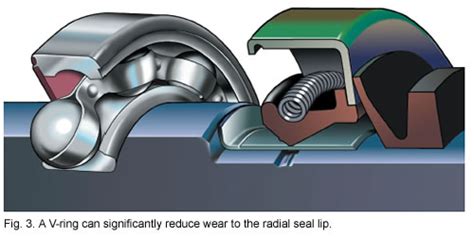

Stein dynamic testing offers true proof-of-concept for new seal designs or materials while delivering peace of mind for repaired seals. Run-to-failure analysis, optimal life expectancy .The Engineering group at ESP International specializes in sealing applications with a focus on radial shaft seal technology and testing. We pride ourselves on our ability to innovate and .To test the integrity of mechanical seals fitted with a secondary containment seal. This document is general in nature and does not refer to site specific requirements. The site has the responsibility for ensuring that tests are carried out.package inflation seal strength test. In the Creep Test, a whole package is inflated to a constant pressure, which is then held for a specified time, resulting in a pass/fail result (see Figure 5). Early users of the method for peelable seals used the test as an analogy for the pressure difference on the seals seen in the ETO

Description. Push Indicator Dye Test is especially developed to check the integrity of your seals produced by your heat sealer, the aluminium package will protect the test ink from light (for Paper and Tyvek packaging).With this ink . This Ink Pouch test or the Dye leak penetration test will show any irregularities that occur (e.g., channels of ink in the seal are a sign of a poor sealing process) and become visible immediately after the single-use dye test pack. It is easy to use, and the process can be documented. (See Figure 2).

Double Column Tensile Tester vendor

Whether in-house testing or field trials, we are able to reproduce ideal and worst-case operating conditions, recording seal integrity, as well as monitoring pressure, speed, temperature, and a number of other performance factors. Hallite Seals test and development facilities include: Friction And Leakage Test Rigs* Hydraulic Cylinder Test Rig*The seal integrity test is a vital procedure in the packaging industry that is used to assess the strength and reliability of seals on packaging materials. This test ensures that the seals, which are crucial for maintaining the safety and quality of the packaged product, are robust and free from defects. Seal integrity is particularly important . Seals should be tested through proper testing methods and standards and then appropriate seals should be selected. This study reviews the dynamic seal test methods for high-pressure liquid .hawo Seal Check hawo Seal Check HDPE. Test system for routine inspection of your sealing device. more > hawo InkTest PRO. The convenient 4-Sides Ink Test. more > hawo InkTest. Classic Triton-X free test system for routine testing of sealing seams. more > ht 150 SCD : 2019. Testing device for the ascertainment of the seal seam resistance for .

Seal tests ISO11607-2 (Validation requirements for forming, sealing and assembly processes), requires Operational Qualification (OQ) of packaging devices to be carried out and documented. The OQ is requiring providing proof of: Intact seal for a specific seal width No channels or open seals No punctures or tears in seals No material delaminating or separation The OQ needs toIt’s important to note that test rigs can accommodate single product testing and complete seal package testing. After all, sealing a hydraulic cylinder is a team effort, requiring all individual parts to interact as expected in unison. Sealing packages need to be carefully selected with the application and customer’s expectation in mind.

EMI/ RFI seals, waveguide seals, spring energized seals, rotary shaft seals, metal gaskets of different shapes. At INFINITIA Industrial Consulting we are experts in materials, innovation and design. If you want to perform a leak test on your materials or develop a new product, contact our prototyping team to offer you the best solution.Download scientific diagram | Test section of high-speed sealing test rig. from publication: Leakage performance of floating ring seal in cold/hot state for aero-engine | Rotating experimental .SEAL TEST MACHINE, find complete details about SEAL TEST MACHINE, SEAL TESTING MACHINE, SEAL TEST, SEAL TESTER - Paper and Package Test Machine Manufacturer. QUALITY COMES FROM TEST. [email protected] +86 13411604920 . . to provide users with accurate heat sealing test index.Sealing technology plays a crucial role in many industrial and consumer products. Seals serve the purpose of preventing leaks and ensuring the safety and efficiency of products, whether it be in the healthcare industry, food industry, or other industries. . It’s like putting a seal through a fitness test to make sure it’s ready for the .

To achieve vacuum level sealing, a maximum surface roughness of 16 μin. (0.41μm) has been recommended.3 Therefore, sealing surfaces on the test fixtures had to have surface finishes of 16 μin. or better. The sealing surfaces on both sides of the interface also had to be precisely aligned so that the amount of compression on the seal test

Dry Gas Seal: This type of seal, which is the most advanced seal of its kind, can perform sealing work in high-pressure compressors up to 550 bar with high reliability without the presence of oil and using interface gas or .

the product. The dye penetration test is considered a destructive test since vis - ible dye is applied to the seal area even though dye present on the external seal area and not the internal seal area would demonstrate that the seal is intact. • Seal strength test. The Standard Test Method for Seal Strength of FlexibleContainment Seal Test Procedure 4.2.5 Set the supply test kit regulator to 0.7 bar g (10 psi g) or above the pressure instrument alarm setting. 4.2.6 Apply the test pressure gradually (refer to point 4.2.4 above) to the containment seal by using the portable test kit. 4.2.7 As pressure increases, check that the pressure alarm Dedicated TestBed (DTB) for detecting the sealing performance of Metal Rubber (MR) was designed and manufactured based on Siemens S7-200 PLC. The experiments, such as high temperature and large temperature difference experiment, could be conducted with real-time monitoring by DTB. The general design including mechanical and control part of DTB is .

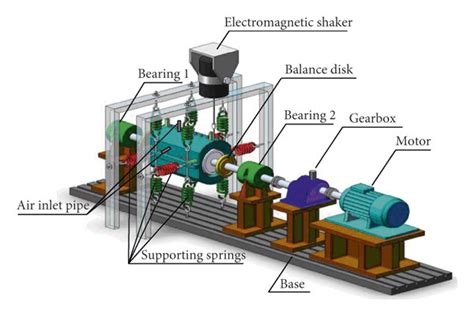

Radial Shaft Seal Testing

For this reason, the test is a poor indicator of seal function at low temperatures. . (ASTM D1329) is currently the most reliable test for low-temperature sealing performance. A rubber seal is . Upon completion of the leak test, carefully depressurize the test rig and disassemble the mechanical seal. Clean all components thoroughly and inspect the seal faces for any signs of wear or damage. If the seal has passed the leak test, it can be prepared for installation or storage as required. Types of Mechanical Seal Leak Test Methods

Maintaining the integrity of packaging is crucial across various industries, from pharmaceuticals to food and beverages. The heat seal strength test method plays a vital role in ensuring that packaging remains secure, protecting the contents from contamination and damage. This article explores the key aspects of heat seal strength testing, with a focus on compliance with ASTM .This is a bolt-on option to our hot oil seal test machines. It allows you to introduce media to the excluding features of the seal. Mixtures of ISO 12103-1 test dust with bentonite clay and water are standard but it is possible to run any media such as belt dust, volcanic ash or water.6. Seal test fixture capabilities Bench testing of rotary shaft seals Figure 2 shows the standard horizontal shaft test fixtures that are used to perform much of our instrumented rotary seal testing. These bench test fixtures are capable of testing seals up to 5” (127 mm) in diameter against various environments. Dynamic sealing test device for shield tail grease under high water pressure was developed. . According to the water pressure seal test device of the shield tail grease, a numerical simulation model was established, as shown in Fig. 18. The thickness of the grease layer was set as 50 mm, and the width of the basin was 50 mm, consistent with .

Carrying out the seal seam stability test. The test process involves several steps: Sample preparation: strips are taken from the sealed seam, typically 15 mm wide. Tensile test: These strips are clamped in the jaws of a tensile machine and pulled apart at a defined speed. The force required is recorded.Test conditions are simulated to be representative of the seal application environment in both sour and sweet service conditions (Tables 2 & 3 respectively). Three temperatures are selected to accelerate results for extrapolation, all of which are higher than service conditions.

WEBana ana de armas ana schultz ana otani ester ana ana gostosa ana castela ana julia ana paula ana lima ana clara ana ester. Ana Mena photos & videos. EroMe is the best place to share your erotic pics and porn videos. Every day, thousands of people use EroMe to enjoy free photos and videos. Come share your amateur.

Seal Test / Sealing Test vendor|Radial Shaft Seal Testing